Design of Jigs and Components for a Dashboard Assembly Line

We were commissioned by a customer in Mexico, building a production line for a supplier in the automotive industry, to conceptualize and design three specialized brackets and jigs. These components were integral to the assembly of car dashboards, specifically designed to hold and push the acrylic panels that cover the vehicle display and gauges.

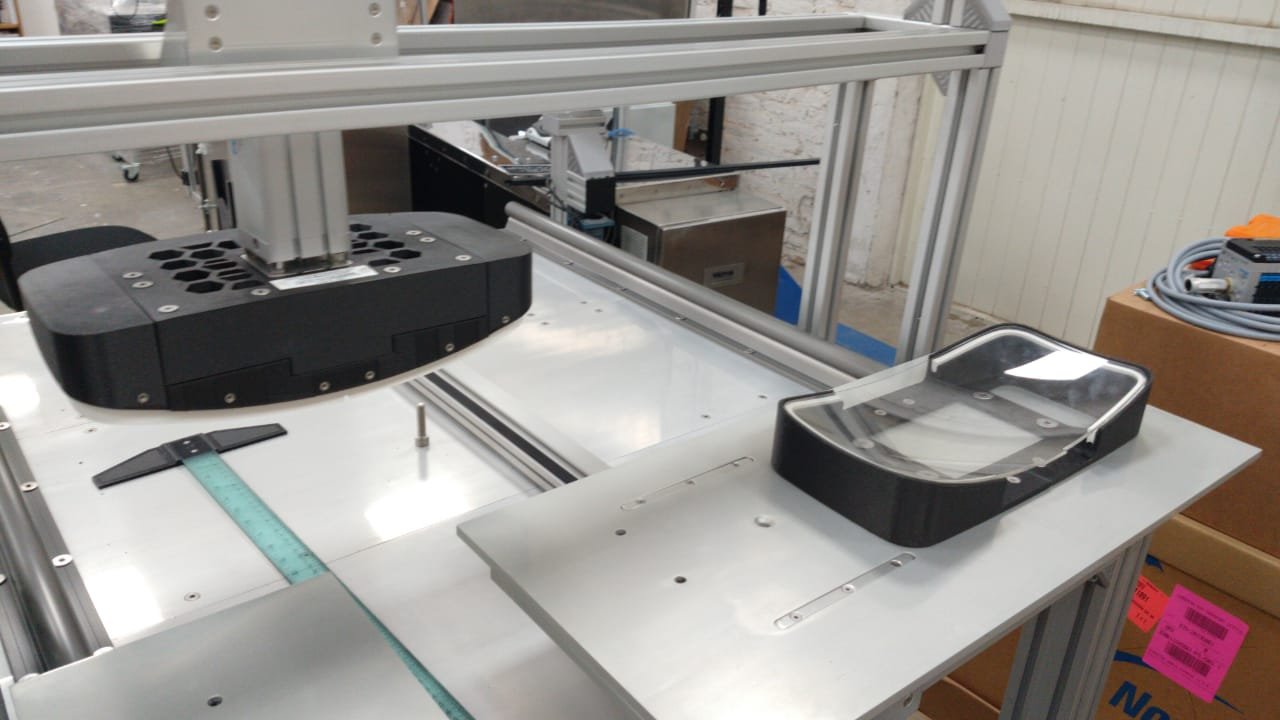

In addition to the brackets and jigs, we also conceptualized, designed the custom grippers for the automated robot that manipulated the acrylics from the injection mold machine to the assembly line. These grippers were engineered to handle the acrylic panels with precision and care, ensuring seamless integration with the production line.

Our involvement began with the conceptualization phase, where we developed and presented several iterations and concepts to the customer. After the final designs were approved, we proceeded to 3D print the brackets, jigs, and grippers using carbon fiber reinforced nylon, ensuring durability and accuracy in the demanding automotive manufacturing environment.

Throughout the project, we were responsive and flexible to meet the customer’s timing and schedule requirements, ensuring that the project progressed smoothly and efficiently.

This project showcases our ability to deliver custom-engineered solutions, from initial concept to final production, tailored to meet the specific needs of the automotive industry.